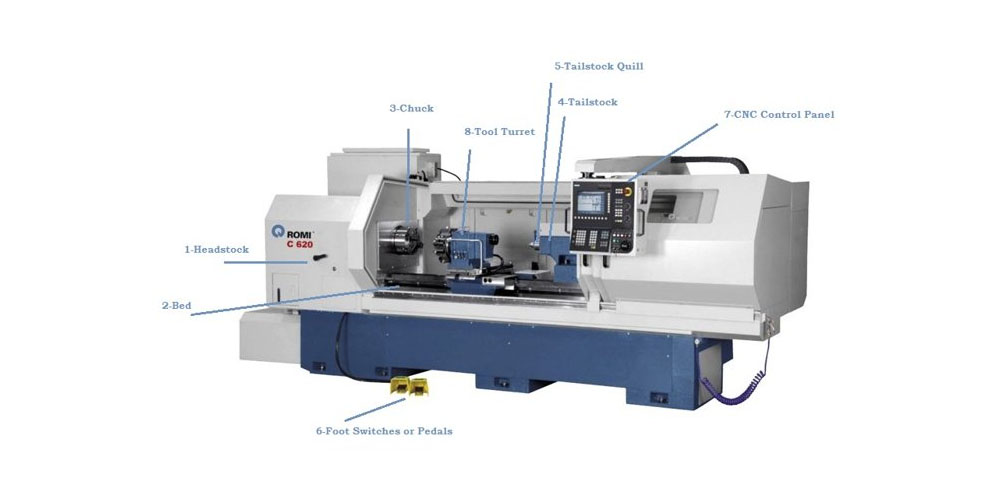

One of the standard machining services is CNC turning. This is a complex and detailed method for creating custom marts using machines known as lathes. The devices use CNC technology to control the movement of the turning tools and the overall production process. In CNC turning, the workpiece is held in the jaw, or a chuck, rotated as the tool is fed to subtract material methodologically. This post discusses the various CNC turning machine components.

Key CNC turning machine components

Like other types of manufacturing machines, CNC turning machines are made up of various components. Each component plays a role in the manufacturing process and the outcome. Below are the critical CNC turning machine components;

1. Door

This component allows operators and engineers access to the machine’s integral parts. For instance, specialists use the door if the turning machine requires maintenance and part replacements. The door usually stays closed during the manufacturing process for safety. The door is generally made from solid materials (bulletproof glass) to prevent the spinning metal from escaping and causing severe damage and injuries.

2. Sheetmetal

This component is designed to protect the operator and the turning machine from any damages or injuries during the process. It is also the component where the cutting chips from the manufacturing process are stored.

3. Spindle

This is the part where the workpiece is attached to the turning machine. The machine usually grips the workpiece using jaws at the spindle. It is also where the turning process takes place. The pressure of the grip via the jaws is generally strong enough to ensure the workpiece does not move. However, it is also not too strong to prevent metal deformation like bending.

4. The chuck

This is the component responsible for holding the workpiece as it rotates. It is also known as the jaw.

5. Tool station and block

The tool station is the component where the cutting tools are attached. On the other hand, the tool block, also known as the tool holder, connects the cutting tools to the tool station. Therefore these components work hand in hand.

6. Turn and face groove tools

The turn tools are used for subtracting material and shaping the workpiece. Different types of devices are used. On the other hand, the face groove tool holds the turning tool in place.

7. Turning center

Also known as the turret, the attached tooling is programmed, and the turning process is conducted. Therefore, it is the backbone of the entire process.

Conclusion

Other than the parts above, other standard CNC turning machine components are;

- Computer- as any CNC machining tool, the turning machine is usually computerized. A computer is used to control the turning components. Various software is used to program the devices via the computer. The operator also monitors the process through the computer.

- Computer keyboard- this component is used to feed instructions or program the machine, depending on the CAD model designed at the beginning of the process.

The computer and keyboard and standard parts are found in all CNC machines regardless of the process.