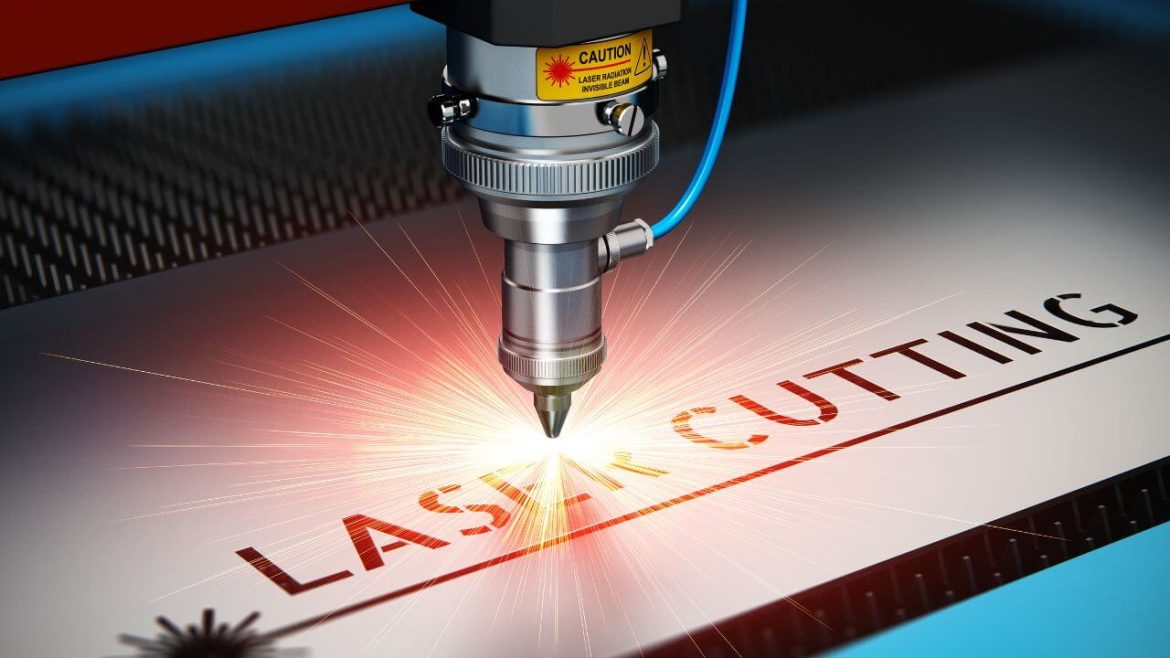

Wrap-around labelers are pivotal in industries requiring precise and seamless application of labels around cylindrical or conical products such as bottles, cans, and tubes. These labelers ensure efficient packaging and branding while demanding high precision in label cutting and application. Laser-cutting technology has emerged as a game-changer in enhancing the accuracy, speed, and versatility of wrap around labeling processes. This article explores the application and benefits of laser cutting technology in wrap-around labelers.

Precision Cutting and Customization

Laser cutting technology offers unparalleled precision in creating intricate shapes and designs for wrap around labels. Unlike traditional mechanical cutting methods, lasers can achieve razor-sharp edges and intricate patterns without physical contact, ensuring clean cuts and minimizing material waste. This precision is crucial in achieving seamless label application around curved surfaces, enhancing product aesthetics and brand visibility.

Versatility in Label Design

One of the key advantages of laser cutting technology in wrap around labelers is its ability to accommodate diverse label designs and materials. Whether it’s paper, plastic, or specialty materials, lasers can precisely cut labels to fit various container shapes and sizes. This flexibility allows for innovative label shapes, windows, and perforations that enhance product differentiation and consumer appeal in competitive markets.

Speed and Efficiency

Laser cutting technology significantly enhances the speed and efficiency of wrap around labeling processes. By automating the cutting and shaping of labels, lasers streamline production workflows and reduce turnaround times. This rapid processing capability is particularly advantageous in high-volume manufacturing environments where quick label application is essential to meet production targets and customer demand.

Reduced Maintenance and Tooling Costs

Unlike traditional mechanical cutting tools that require frequent maintenance and replacement, laser cutting systems are known for their durability and minimal upkeep requirements. This reduces downtime and operational costs associated with tooling maintenance, ensuring continuous production and maximizing equipment utilization in wrap-around labelers.

Enhanced Safety and Quality Control

Laser-cutting technology prioritizes safety and quality control in wrap-around labeling operations. Advanced laser systems incorporate safety features such as automated shut-off mechanisms and protective enclosures to prevent accidents and ensure operator safety. Additionally, lasers offer precise control over cutting parameters, ensuring consistent label quality and adherence to strict industry standards for packaging and labeling.

Environmental Sustainability

Laser-cutting technology supports environmental sustainability initiatives in wrap-around labeling applications. By optimizing material usage and minimizing waste through precise cutting, lasers contribute to reduced carbon footprint and sustainable manufacturing practices. This aligns with industry trends towards eco-friendly packaging solutions that meet consumer preferences for environmentally responsible products.

Integration with Digital Printing Technologies

The integration of laser cutting with digital printing technologies further enhances the capabilities of wrap-around labeller. Digital printing allows for on-demand customization of labels with variable data, graphics, and colors, while laser cutting ensures precise finishing and customization of label shapes. This synergy enables manufacturers to respond quickly to market demands for personalized packaging and promotional campaigns.

Conclusion

Laser-cutting technology revolutionizes wrap-around labeling by offering unmatched precision, versatility, and efficiency in cutting and customizing labels for cylindrical and conical containers. Its ability to enhance productivity, reduce costs, ensure quality, and support sustainability makes laser cutting a preferred choice for manufacturers seeking to optimize wrap-around labeling processes and enhance brand presence in competitive markets.